Charles Edward Mason

- Born: 25 Jan 1847, Providence RI

- Marriage (1): Lydia Carpenter Bliss on 20 Nov 1872 in Attleboro MA

General notes:

Jeweler

Events in his life were:

- He appeared on the 1870 census taken at Attleboro MA, listed as a jewelry worker.

- He appeared on the 1880 census taken at Attleboro MA, listed as a jewelry manufacturer, living with his father-in-law, Rudolphus Bliss.

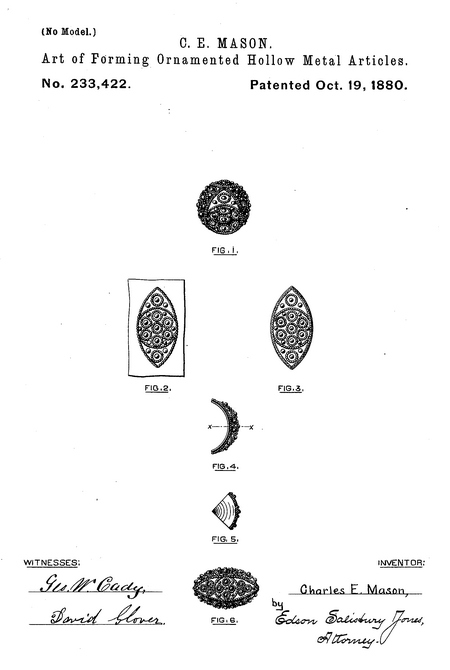

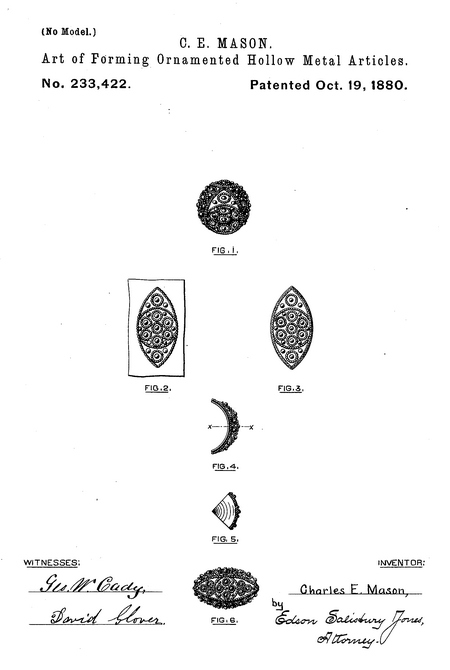

- He was issued patent number 233,422 on 19 Oct 1880

CHARLES E. MASON, OF ATTLEBROROUGH, MASSACHUSETTS.

ART OF FORMING ORNAMENTED HOLLOW METAL ARTICLES.

SPECIFICATION forming part of Letters Patent No. 233,422, dated October 19, 1880. Application filed July 8, 1880.

To all whom it may concern:

Be it known that I, Charles B. Mason, of Attleborough, in the county of Bristol and State of Massachusetts, have invented a new and useful Improvement in the Art of Forming Ornamented Hollow Metal Structures for Jewelry; and I do hereby declare that the following specification, taken in connection with the accompanying drawings, forming a part of the same, is a full, clear, and exact description thereof.

My invention relates to the method of forming spherical, spheroidal, and other shaped hollow metal structures having raised ornaments upon their surfaces for necklaces, scarf-pins, and other articles of jewelry.

My improvement consists in producing a metal blank having the outline of the developed envelope of a section of the structure to be made, and having raised ornamental portions which are integral with the metal composing the blank, swaging such blank into the shape of a section of such structure, and finally uniting a number of such sections to produce the finished article.

Referring to the drawings, Figure 1 represents a hollow spherical structure or ball composed of four surface - ornamented sections, the ornament being in imitation of twisted wire and diminutive spheres soldered upon the surface of a ball. Fig. 2 represents a flat piece of sheet metal with, parts of its surface ornamentally raised above the surrounding portion and integral therewith. Fig. 3 shows the ornamented part when removed from the sheet, and provided with a proper outline to form a blank. Fig. 4 represents a side view of a section of a spherical ball formed from said blank. Fig. 5 shows a transverse section, on line x x of said section, of a spherical ball; and Fig. 6 represents a spheroidal structure or ball having raised ornaments upon its surface.

Spherical balls having raised ornaments of the character shown upon their surfaces have been made heretofore in the following manner: A piece of sheet metal is swaged into the form of a hollow ball, or two pieces of sheet metal are swaged into hemispheres and united. Pieces of twisted wire bent into the desired shapes and diminutive spheres are then separately soldered upon the surface thereof to form the ornamental portion and complete the structure. This mode of manufacture has been exceedingly expensive. It has also been unsatisfactory, for the reasons that the members composing the ornament have not been exactly placed, and are quite liable to become detached, thereby producing an unsightly appearance.

The objects of my improvement are to materially reduce the expense of manufacturing this variety of jewelry, to secure absolute accuracy in the location of the details of the ornament, and to produce an article the raised ornamental portions of which are integral with the metal composing it, thereby avoiding the danger of disfigurement by a loss of a portion of said ornament.

I will now describe the preferable method by which I accomplish these results when hollow structures of gold, "stock-plate," or base metal are to be made.

In forming hollow spherical balls, for example, pieces of sheet metal are separately placed upon a die whose surface has been supplied with the desired design engraved to a proper depth, and each is struck until portions of the surface are desirably raised and ornamented, as shown in Fig. 2. The ornamented part is then cut or punched from the sheet and a flat blank produced having a proper outline, as shown, in Fig. 3. By means of a die, of wood or other suitable material, having a properly-shaped cavity and follower, the blanks are swaged into sections of a hollow sphere, as shown in Figs. 4 and 5. The proper number of these sections are then united and the article is completed, as shown in Fig. 1.

A spheroidal ball, as shown in Fig. 6, and hollow structures of other shapes are formed in a similar manner, the only difference residing in the shape of the blanks from which the sections are formed and the contour given to such sections.

The number of sections which are united to form a structure varies with the size and character of such structure, two or more sections being employed.

In place of forming complete spherical or spheroidal structures from the sections, a less number of sections than is necessary to form such complete structures may be used to produce various articles of jewelry.

Although I have described the method which I preferably employ to form the flat ornamental blanks, I have also produced such blanks by making an electro-deposit of metal upon a matrix of proper material, the reverse of the blanks. Blanks formed in this manner are treated as above described to produce sections of a structure.

Having described my invention, what I claim, and desire to secure by Letters Patent, is'97

1. The improvement in the art of forming spherical, spheroidal, and other shaped hollow metal structures having a raised ornamental surface, which consists in forming flat blanks having raised ornamental portions which are integral with the metal composing the blanks, substantially as described, swaging said blanks into the form of sections of said structure, and uniting a number of said sections, substantially as set forth.

2. The improvement in the art of forming a section of a spherical, spheroidal, or other shaped hollow metal structure having raised ornament upon its surface, which consists in forming a flat blank having raised ornamental portions which are integral with the metal composing said blank, and swaging such ornamented blank into the form of a section of the structure, substantially as set forth.

3. As an improved article of manufacture, a spherical, spheroidal, or other shaped hollow metal structure composed of united sections having raised ornamental portions which are integral with the metal composing said sections, substantially as set forth.

Charles E. Mason

Witnesses:

Edson Salisbury Jones

John D. Thurston

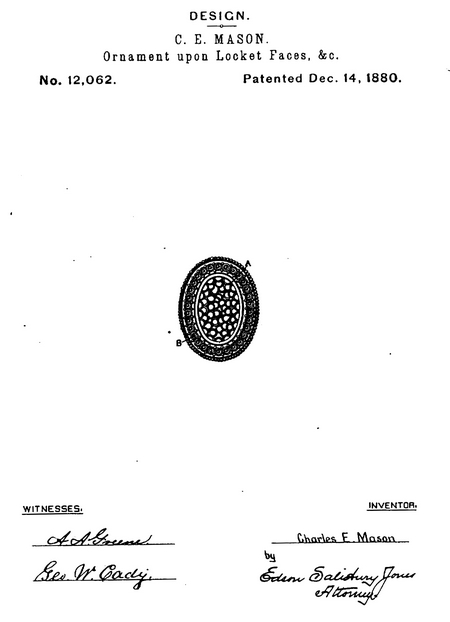

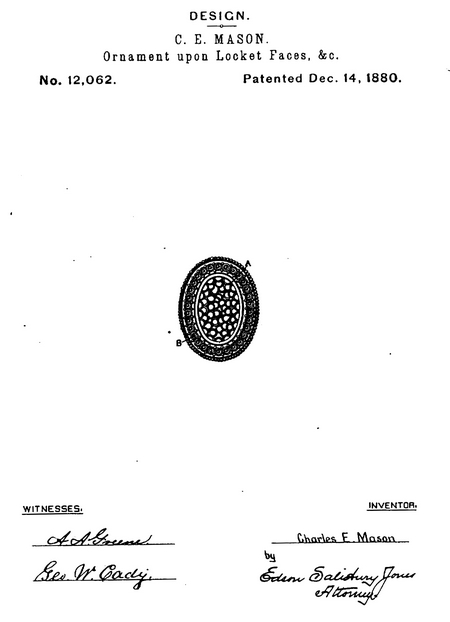

- He was issued design patent number 12,062 on 14 Dec 1880

CHARLES E. MASON, OF ATTLEBOROUGH, MASSACHUSETTS.

DESIGN FOR ORNAMENT UPON LOCKET-FACES, &,c.

SPECIFICATION forming part of Design No. 12,062, dated December 14, 1880.

Application filed November 4, 1880. Term of patent : 3 1/2 years.

To all whom it may concern:

Be it known that I, CHARLES E. MASON, of Attleborough, in the county of Bristol and State of Massachusetts, have invented a new and useful Design for Ornament Upon the Faces of Lockets and Other Articles of Jewelry; and I do hereby declare that the following specification, taken in connection with the accompanying drawing, forming a part of the same, is a full, clear, and exact description thereof.

My design relates to the composition and arrangement of ornament upon the faces of lockets and other articles of jewelry; and it consists of the following features: The central surface of the face of the article is surrounded by a raised band, A, and said surface is ornamented by segments of rings superimposed thereon. Outlying and surrounding the band A is a border, B, composed of rings and spheres or hemispheres, the said rings being adjacent to each other and the spherical portions occupying positions in the centers of and between said rings. The whole may be surrounded, if desired, by a bead border, as shown; but such border forms no part of the design, and may be omitted or changed in character.

Although, as represented in the drawing, the ornament is arranged upon a surface having the outline of an ellipse, yet said surface may have a rectangular or circular contour, and the ornament be arranged concentric therewith without changing the character and arrangement of the parts of the design, the essential features of which are segments of rings upon a central surface, a surrounding raised band, A, and an outlying and surrounding border, B, composed of rings and spheres or hemispheres.

Having described my invention, what I claim, and desire to secure by Letters Patent, isó

The design for ornament upon the faces of lockets and other articles of jewelry, substantially as set forth.

Charles E. Mason

Witnesses:

W. H. Thurston

Edson Salisbury Jones

Charles married Lydia Carpenter Bliss, daughter of Rudolphus Bliss and Lydia Carpenter, on 20 Nov 1872 in Attleboro MA. (Lydia Carpenter Bliss was born on 5 Jan 1849 in Attleboro MA.)

|