Sandford Boon

- Born: 8 Jul 1799

- Marriage (1): Lucretia Goldsmith

- Died: 4 Dec 1857, Galesburg IL

General notes:

Silversmith and jeweler

Events in his life were:

- Partnership: Daniel D. R. Ormsby, before 1834, in Cortland NY. As BOON & ORMSBY.

- He worked in 1836 as a jeweler in Hamilton NY

- He was issued patent number 848 on 19 Jul 1838

SANDFORD BOON, OF HAMILTON, NEW YORK.

PLATING-MILL FOR MAKING SPOONS.

Specification of Letters Patent No. 848, dated July 19, 1838.

To all whom it may concern:

Be it known that I SANDFORD BOON, of Hamilton, in the county of Madison and State of New York, have invented a new and useful Improvement in Plating-Mills or Machines used by Silversmiths, the improvement being designed for making or manufacturing Spoons; and I do hereby declare that the following is an exact and full description of said invention or improvement.

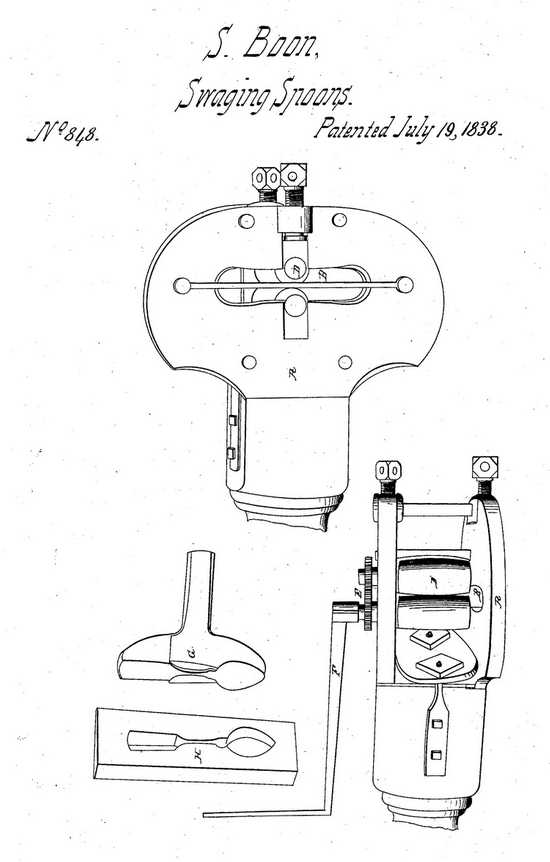

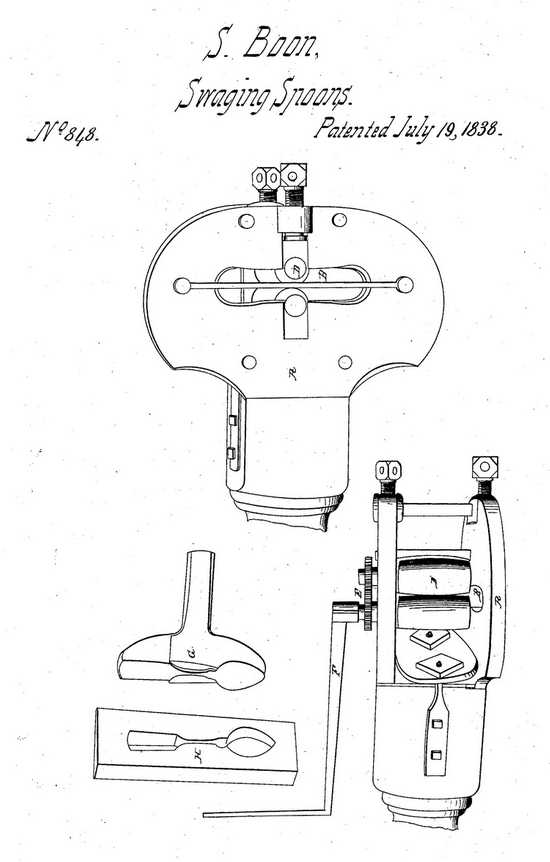

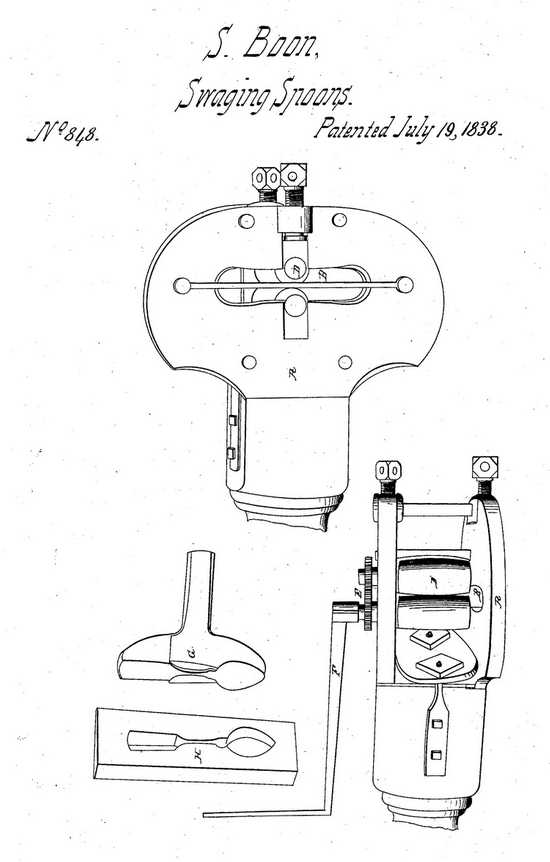

The nature of my invention consists in applying to the said plating mill or machine, convex rollers or rather in substituting for the two common rollers of said plating mill or machine rollers the diameter or thickness of each roller being unequal, presenting a surface on each roller so varied or convexed, as to give to the silver or other metal worked and passed through and between them, the different and varied thicknesses required in the different parts of a spoon; but I put the principal part of the convex on one roller and by having one extra roller to change, so as to have a long and short convex. The same mill or machine makes both table, and tea spoons; and an open or skeleton plate into which one end of the improved rollers are inserted, and through the opening in which plate the piece of metal is passed into or between the said rollers, and also in the application of a bar fastened to the said plate in front of the opening, the bar serving as a gage bar.

To enable others skilled in the art, to make and use my invention, I will proceed to describe its construction and operation. I construct my plating mill or machine in the known form of plating mills or machines, except that the power is applied at one end of the rollers, or machine and by the means of cogs. I then make one side of the frame or plate (called a skeleton plate) with an opening sufficiently large to pass the piece of metal to be worked, between and through and from the rollers, and the gage bar is placed across this opening horizontally.

In the manner of working and using this mill or machine, the silver or other metal to be used, is worked down into bars or rods, the length I want my spoons when finished, and as thick as I want to have the thickest part of the handle of the spoon, and as wide as I want the shoulder where the handle comes on to the bowl. The bars are then marked so as to have the required length of the metal for one end of the spoon to pass through the rollers; and each bar is then passed through the rollers, keeping the said mark upon the front side of the gage bar. The metal is then passed through an opening in the skeleton plate, under the gage bar endwise; entering the rollers sidewise of the bar of metalto be worked, so much of the bar in length passing into the rollers as forms the bowl or handle of the spoon; it being immaterial whether the bowl or handle is first worked.

In working the bowl of the spoon, the bar is passed between the rollers until the metal is brought to about two thirds the width I want the bowl when finished. The rollers are then turned back and forth a few times, without taking the metal from between them. This is done in order to throw more of the metal from the center of the bowl, and leave it thicker on the sides or edges of the bowl, the convex on the rollers giving the required thickness at the heel and point. After the bowl is thus worked, I then throw down the back screw and raise the front one, which is on the skeleton plate. I then reverse the spoon and pass it through the rollers, as above described; except the " turning back and forth" until the metal is worked down to the thickness required for the handle. By thus altering the screws the same convex on the rollers will give the different thickness to the handle. After the metaL has received its proper size and thickness from the rollers as above stated, it is then placed between a stamp and sink which cuts arid trims the edges and sides and gives the spoon its proper shape; the bowl is then raised and the spoon finished in the usual manner. The drawings hereto attached represent my improved plating mill or machine and also the parts claimed by me as my invention. The plate marked A represents the open or skeleton plate. B represents the opening in said plates; C the gage bar; D the convexed rollers. E represents the cogged wheels on the ends of the rollers and F the crank. The sink and stamp used for shaping and cutting and trimming the spoon is represented by the drawings marked G and H.

What I claim as my invention, and desire to secure by Letters Patent, isó

The combination of the skeleton plate, gage bar and rollers, in manner substantially as herein described.

Dated April 9th 1838.

Sandford Boon

Witnesses:

William Fairchild

Jas. I. Dewey

- He appeared on the census in 1850 in Galesburg IL. Listed as a watchmaker.

Sandford married Lucretia Goldsmith. (Lucretia Goldsmith was born on 16 Jul 1802.)

|