Edwin Hayne Rowley

- Born: 1835, Connecticut

- Marriage (1): Amy Brush on 31 Mar 1859 in New York City NY

General notes:

Pewtersmith and silverplater

Events in his life were:

- Partnership: Stephen Curtis, circa 1870, in New York City NY. As CURTIS & ROWLEY, with a shop at 90 Fulton Street.

- He witnessed patent number 143,334 on 30 Sep 1873

STEPHEN CURTIS, OF NEW YORK, N. Y.

IMPROVEMENT IN CASTERS.

Specification forming part of Letters Patent No. 143,334, dated September 30, 1873

To all whom it may concern:

Be it known that I, Stephen Curtis, of New York, in the county of New York and State of New York, have invented a new and useful Improvement in Casters; and I do hereby declare the following to be a full, clear, and exact description of the same, reference being had to the accompanying drawings, in which—

Figure 1 is a sectional plan view of one of my caster-frames. Fig. 2 is a central sectional elevation of the same. Fig. 3 is a similar section, showing the position of the band-edge before the center is secured in place. Figs. 4 and 5 represent a modification of the method of manufacture.

This invention relates to an improved method of manufacturing the bottle-frame, whereby the same is greatly strengthened and reduced in cost; and it consists of a center constructed separate from the band, and with a continuous rim extending outward sufficiently far all around to meet said band and be secured thereto; and it also consists in uniting said center and band without solder.

Heretofore the bottle-rings have been cast without any rim, and they therefore only touch the band at those points which are most distant from the center of the frame, and therefore from one bottle-ring to another the band receives no support from the center, and is easily crushed in or indented.

I am aware that bottle-frames have been made with the band extended in a single plate to the center standard; but when so made the ordinary center frame is also employed, and is soldered to said plate on its lower side.

Heretofore, also, the cast center has always been united to the band by solder, which operation, on account of its delicacy, requires great skill, and is therefore costly.

By means of the continuous rim, which is the subject of this invention, the band is supported and strengthened, and may be united to said center without the use of solder, the edge of the band being compressed or turned down over the edge of said rim, and this operation, being entirely mechanical, may be performed with great facility, and without the exercise of great skill on the part of the operative.

That others may fully understand my improvement, I will particularly describe it.

A represents a bottle-frame constructed with a center, a, having a continuous rim, b, extending from one bottle-ring to another, and so on all around, meeting and being secured to the band c, so as to strengthen and support the same against crushing or indentation.

It is evident that it is immaterial, so far as the strengthening of the band is concerned, whether the rim b and band c are soldered together or otherwise united, and I therefore do not, in this part of my invention, confine myself to any particular method of securing said parts together; but, for reasons of economy above stated, I prefer to dispense with solder and unite said center and band by compressing or turning down the metal of the band over the edge of the center, as shown in Figs. 2 and 5. This operation maybe performed by methods well understood.

By this method the variety of forms, either ornamental or useful, is not circumscribed, while the cost of production is greatly reduced without any reduction in quality of goods.

Having described my invention, what I claim as new is-—

1. The center a, constructed with a continuous rim, b, and separate from the band e, substantially as and for the purpose set forth.

2. As a new article of manufacture, a bottle-frame for casters constructed with center and band in.separate parts, united without solder by turning, the edge of one over the edge of the other, substantially as set forth.

Stephen Curtis

Witnesses:

Edwin H. Bowley

Henry Stix

- He was issued patent number 165,071 on 29 Jun 1875

STEPHEN CURTIS AND EDWIN H. ROWLEY, OF NEW YORK, N. Y.

IMPROVEMENT IN LADLES.

Specification forming part of Letters Patent No. 165,071, dated June 29, 1875

To all whom it may concern:

Be it known that we, Stephen Curtis and Edwin H.Rowley, both of the city, county, and State of New York, have invented a new and useful Improvement in Ladles; and we do hereby declare that the following is a full, clear, and exact description thereof, reference being1 had,to the accompanying drawing, making part of this specification.

This invention has for its object to furnish a strong, durable, and attractive ladle, which will not corrode or tarnish, and possesses many advantages over the ordinary ladle constructed of britannia or other soft metal; and our invention consists of a ladle composed of a bowl constructed of an internally-enameled lining or body of bard metal to retain its shape, and an external covering of soft metal spun Over and upon the lining or body, and secured thereon by bending its upper edge down over the edge of the lining-piece and enameled lining, all of which will be fully hereinafter described.

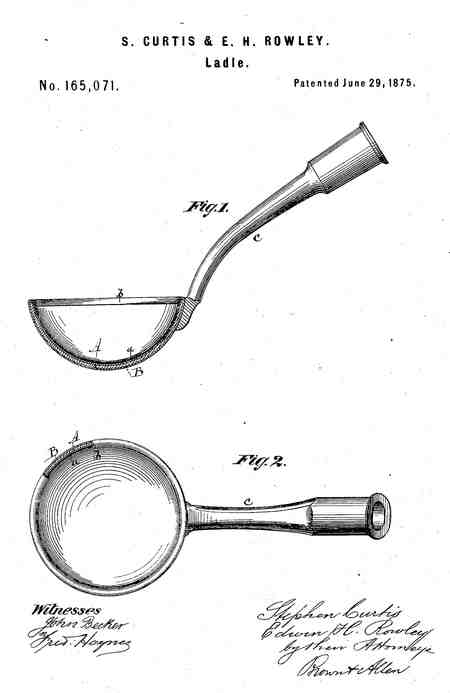

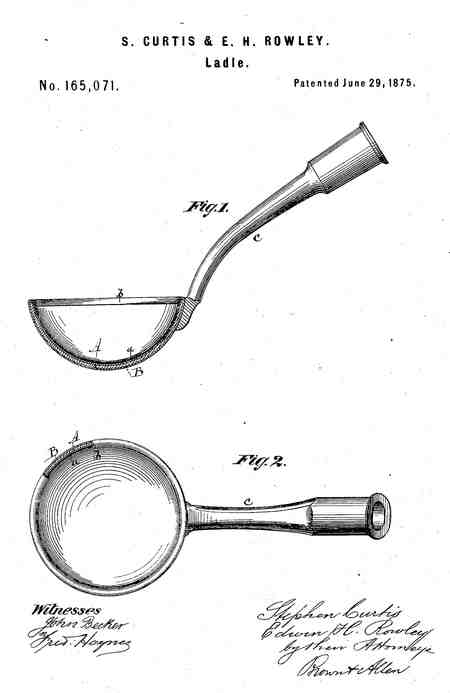

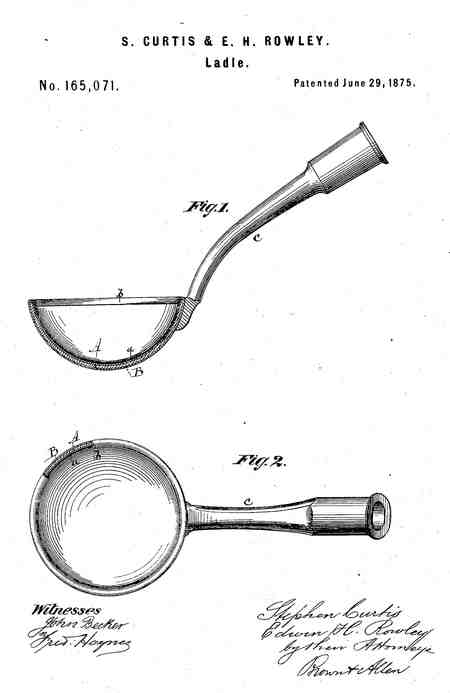

In the accompanying drawing, Figure 1 is a sectional view of our improved ladle. Fig. 2 is a top view.

The bowl of the ladle is composed of a lining-piece, A, and an external covering, B, and the handle c is or may be attached to the bowl by soldering or in any suitable manner. The lining-piece A is made of iron, or other hard metal which will retain the proper shape and not be easily battered or dented. It may be of cast-iron or of wrought-iron, stamped into shape, and it is enameled on its concave or inner surface, as shown at a. The external covering B is made of britannia or other suitable soft, light metal, and is spun over the back of the lining-piece A, and secured by turning down its edges b over the edges of the hard lining piece and enameled lining, as shown in Fig, 1. After the bowl is thus formed, the handle c is attached by soldering or in any other suitable manner. The bowl of the ladle thus constructed is stronger and more durable than one made entirely of soft metal, and will retain its shape and not be easily battered, bent, or dented, and yet will present a neat appearance, and may be made and sold at small cost.

We design that our invention be restricted strictly to the manufacture of ladles, as specifically pointed out hereinbefore, and we do not wish to be understood as claiming, broadly, articles formed of hard metal, "dry-plated" with soft metal, to which an ornamental polish is imparted.

What we claim as new, and desire to secure by Letters Patent, is-—

As an article of manufacture, a ladle consisting of a bowl of an internally-enameled lining or body of hard metal to retain its proper shape, and an external covering of soft metal spun over and upon the lining or body, and secured thereon by bending its upper edge down over the edge of the lining-piece and enameled lining, as and for the purpose herein shown and described.

Stephen Curtis

Edwin H. Rowley

Witnesses:

Michael Ryan

Fred. Haynes

- He appeared on the census in 1880 in New York City NY. Listed as a britannia manufacturer.

Edwin married Amy Brush on 31 Mar 1859 in New York City NY. (Amy Brush was born on 28 Apr 1836 in Smithtown NY and died on 2 Oct 1863.)

|