Frederick J. Seymour

- Born: 14 Oct 1824, Watertown CT

- Marriage (1): Florintine M. Migeon on 28 Aug 1849

General notes:

Manufacturer

Events in his life were:

- He was issued patent number 134,938 on 14 Jan 1873

FREDERICK J. SEYMOUR, OF WOLCOTTVILLE, CONNECTICUT. IMPROVEMENT IN MACHINES FOR MAKING BRASS KETTLES AND OTHER HOLLOW-WARE.

Specification forming part of Letters Patent No. 134,938, dated January 14, 1873.

To all whom it may concern:

Be it known that I, Frederick J. Seymour, of Wolcottville, in the county of Litchfield and State of Connecticut, have invented and made an Improvement in Machinery for Making Brass Kettles and other hollow articles and the following is declared to be a correct description thereof.

Machinery has heretofore been made for spinning up sheet metal into kettles and other hollow articles. Where a mold or form has been employed, and the metal rolled upon the same into shape, the metal is very liable to draw into crimps and folds before being acted upon by the tool; hence, when compressed by the tool, it is liable to be injured, and not be of perfectly uniform thickness, because the crimps or flutes thicken more at some places than at others as drawn down. The consequence is that the kettle has to be reduced by gradual stages, and annealing is required between each reduction. In cases where rollers have been employed to bring the sheet metal into shape, the reduction can only be small at each successive operation, or else the general shape of the kettle would be distorted and irregular, and may be broken in the operation.

In spinning up sheet metal by hand it is usual to employ what is known as a " back-burnisher," viz., a stick of wood or implement held by hand, to prevent the formation of corrugations or wrinkles in the metal.

My present invention is made for the purpose of forming kettles or other hollow articles upon a form or shape at once by two conjoint reductions; thereby the metal is held so that folds, corrugations, or crimps cannot be formed, and a much greater reduction can be obtained at once than was heretofore possible. In most instances this mode of forming articles can be used to produce the complete kettle at once; or it may be employed as a preliminary operation before the final complete shaping of the hollow article.

I make use of two reducing-tools; the first acts to shape the metal upon the revolving form and bring it to the proper thickness; the second tool acts against the first, to partially reduce the metal in thickness and present it to the first tool for final shaping upon the form, and at the same time the second tool keeps the sheet of metal out in the form of a curved or flat ring, and prevents the formation of folds, creases, or corrugations.

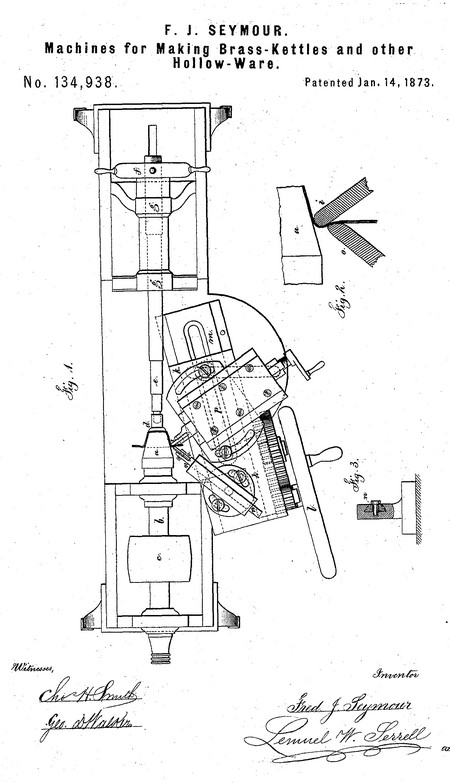

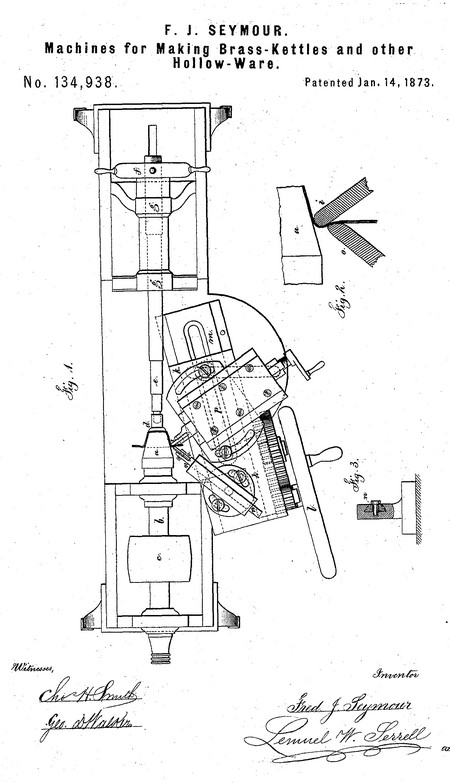

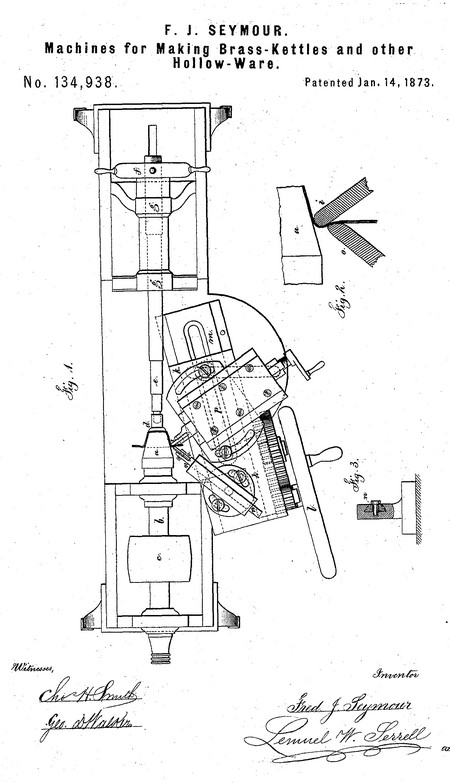

In the drawing, Figure 1 is a plan of the machine employed by me. Fig. 2 is a section in larger size, representing the two reducing-tools as they act upon the sheet of metal; and Fig. 3 is a section of the slide holding the second tool.

The shape or form a is mounted upon the end of the mandrel b, and revolved by competent power applied to the pulley e. This form a is changeable, so that it may be removed and another placed upon the mandrel. The clamping button or disk d is actuated by the bar e and screw-wheel f, and the head g supports these parts; and 1 remark that they may be of any desired construction.

The reducing-tools i and o are shown as rollers. I prefer these; but burnishers might be employed, and more than two may be made use of.

Where the kettle or hollow article is made with straight sides, the tools i and o are to be mounted in a rest, k, that is moved along by a hand-wheel, I, and gearing or otherwise over the bed m; but where the article to be produced does not have straight sides, the tools i o may be set in yielding slides or bearings, as in my patent of August 11, 1868.

The tool o should be mounted at the end of the slide n, seen in Figs. 1 and 3, and is adjusted to position, but may be fixed firmly thereafter. The tool i should be in the slide-rest p so as to be brought back out of the way of the disk or blank when first introduced, and, as it is projected to place, it will commence the spinning or forming operation at the bottom edge of the shape or form a, and then, when the tool i has been brought up contiguous to the form a and tool o, the two will be moved lengthwise of the kettle and reduce the blank directly to the shape of the form, there being one reducing operation between the tools i and o, and the other between the tool i and form a, and at the same time the sheet of metal or blank will be kept in shape and not draw into folds or creases under the most severe reduction to which the metal can safely be subjected.

I claim as my invention—

The tools i and o, in combination with the revolving form a, for reducing a sheet-metal blank into a kettle or hollow article, substantially as set forth.

Signed by me this 20th day of January, 1872.

Frederick J. Seymour

Witnesses:

Geo. T. Pinckney

Harold Serrell

- He appeared on the census in 1880 in Torrington CT. Listed as a manufacturer.

Frederick married Florintine M. Migeon, daughter of Henri Migeon and Mary Louise Beaudelot, on 28 Aug 1849. (Florintine M. Migeon was born on 26 Aug 1827 in Sedan, Ardennes, France.)

|