Nathaniel Grant

- Born: 9 Sep 1833, York ME

- Marriage (1): Elizabeth Spencer Richards on 2 Nov 1856 in Attleboro MA

- Died: 8 Sep 1889, Attleboro MA

General notes:

Jeweler

Events in his life were:

- He appeared on the census in 1860 in Providence RI. Listed as a colorer of jewelry.

- He appeared on the census in 1870 in Providence RI. Listed as a manufacturing jeweler.

- He was issued patent number 217,279 on 8 Jul 1879

NATHANIEL GRANT OF PROVIDENCE, RHODE ISLAND

IMPROVEMENT IN JEWELRY.

Specification forming part of Letters Patent No. 217,279, dated July 8, 1879; application filed November 21, 1878.

To all whom it may concern:

Be it known that I, Nathaniel Grant, of the city and county of Providence, and State of Rhode Island, have invented a new and useful Improvement in Jewelry; and I hereby declare that the following is a full, clear, and exact description of the same, reference being had to the accompanying drawings, forming part of this specification.

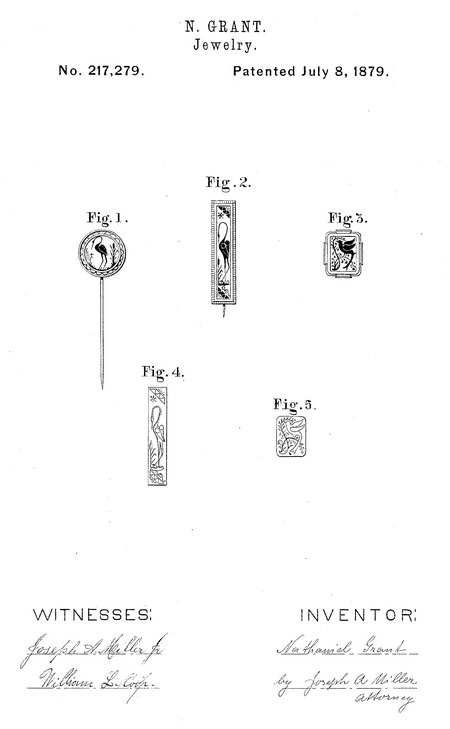

Figure 1 represents a scarf-pin with a circular panel, on which designs and ornaments are enameled. Fig. 2 represents a shawl-pin provided with an ornamented panel. Fig. 3 is a view of a stud or button provided with enameled panel. Figs. 4 and 5 represent plates on which figures or designs are stamped, so as to form sunken lines, into which the enamel is placed and secured.

The invention has reference to an improved method and article in jewelry, in which enameled panels are used; and consists in the combination of the successive steps by which an enameled panel is produced at such low cost that it can be used in plate-jewelry and still present the appearance of the costly enameled jewelry, all of which will be more fully set forth hereinafter, and pointed out in the claims.

Enameled panels may be produced in two ways, both of which have been practiced for a long time, viz: The first and most costly by painting with verifiable colors on an enameled or glazed surface; and the second by forming with a graver on the surface of gold, silver, copper, or other metals, cells or pockets, separated by edges, and filling each cell with the desired colored oxides. To this second method the improvement applies; and it consists in first stamping the various pockets or cells forming the design on a suitable piece of copper, brass, or other metal, by a die under a drop-press, so as to form sharp and clean partitions between the pockets.

The differently colored enamels are now placed into their respective pockets or cells, and the plate subjected to sufficient heat to melt the enamel and unite the same with the "metal," as it is technically called. The plate is fired. When cool the whole surface of the panel is cleaned, the metal surfaces are then colored with metal by electro-deposition or otherwise, and then the whole is covered with a transparent glaze or enamel, which protects the metallic surface, and preserves the finish and luster of the coloring.

Various effects of coloring are produced by plating with a battery connected with a solution of silver, a solution of copper, and a solution of gold, all three of which metals are thus deposited ; and when a light whitish effect is desired, the silver solution is made strong and the others weak; if a reddish color, the copper is made the strongest, and so with the gold. Such a deposit produces a fine color; but such a color is more liable to tarnish; and to protect the same, the whole is covered with a transparent enamel.

These enameled panels are secured within stamped frames made of light stock-plate, and when finished present an elegant and highly artistic appearance. They are durable, and can be made at a low price.

In the old process great care and skill were required to cut all the different cells and preserve the walls or division-lines, so as to prevent the mixing of the different colors when subjected to the firing, and also cut these partitions sufficiently thin so that they would not separate the colors too much. By stamping the cells with a well-cut die under a drop-press by a sadden blow, the cells forming the design are cheaply, sharply, and perfectly produced.

In the old method the metal in which designs or ornaments were enameled was not protected by enamel except where the mosaic design was inlaid. In my improved process I color the metal so as to impart to it the appearance of fine gold, and then cover and protect the whole by a transparent enamel, which is permanently secured to the panels by firing.

Having thus described my invention, I claim as new and desire to secure by Letters Patent—

1. The process for producing enameled panels for jewelry, which consists in the following-named steps: first, stamping in the cells or depressions forming the design by suitable dies; second, filling said cells with enamel; third, firing the same; fourth, coloring the surface of the base metal with a purer metal by electro-deposition or otherwise; and, fifth, protecting the whole surface by means of a transparent enamel ; and, lastly, firing the same, substantially as described.

2. As a new article of manufacture, an ornamental panel for jewelry, composed of a plate of base metal, having enamel designs of different colors, separated by metal lines raised from the metal backhand colored by a purer metal, and the whole face of the panel covered and protected from corrosion by a vitrified glaze, substantially as and for the purpose described.

Nathl Grant

Witnesses:

Joseph A. Miller

Joseph A. Miller, Jr.

- He appeared on the census in 1880 in Providence RI. Listed as a manufacturing jeweler.

Nathaniel married Elizabeth Spencer Richards, daughter of Spencer Richards and Betsey French, on 2 Nov 1856 in Attleboro MA. (Elizabeth Spencer Richards was born in 1833 in Attleboro MA.)

|