George Henry Sackett

- Born: 24 Aug 1826, Providence RI

General notes:

Jeweler

Events in his life were:

- He worked in 1855-1878 as a jeweler in Providence RI for the firm of SACKETT, DAVIS & Co.

- He appeared on the census in 1880 in Brooklyn NY. Listed as a merchant.

- Patent: 349,753, on 28 Sep 1886. GEORGE H. SACKETT, OF BROOKLYN, NEW YORK, ASSIGNOR TO NICHOLAS SHELDON, OF PROVIDENCE, RHODE ISLAND.

FOUNTAIN-PEN

SPECIFICATION forming part of Letters Patent No. 349,753, dated September 28, 1886.

Application filed March 20, 1886. Serial No. 195,957

To all whom it may concern:

Be it known that I, George H. Sackett, of Brooklyn, in the county of Kings and State of New York, have invented certain new and useful Improvements in Fountain-Pens, of which the following is a specification.

My invention relates to fountain-pens; and the invention consists in certain novel features of construction, as hereinafter more fully set forth.

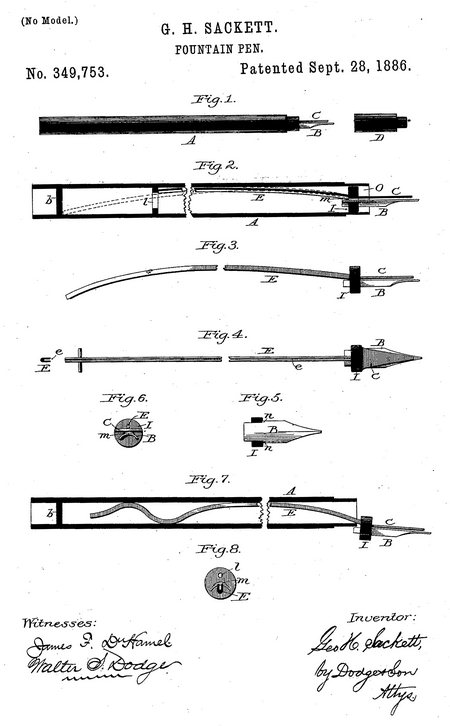

Figure 1 is a side view of my improved pen of the full size. Figs. 2 and 7 are longitudinal sections of the same on an enlarged scale. Figs. 3, i, 5, 6, and 8 are views of portions detached and enlarged, showing the details of construction.

It has long been essayed to produce a fountain-pen in which the ordinary gold or similar pen-point can be used, which will contain a proper supply of ink and not be liable to drop the ink when handled, and which shall not be too large or clumsy to handle conveniently, and which will not smear the finger when used, and which at the same time will feed the ink from the reservoir to the pen-point with certainty and uniformity, and remain at all times ready for immediate use; and though pens have been produced which to some extent fulfill the requirements, or some of them, still they have not given entire satisfaction, and have not therefore come into general use.

The object of my present invention is to produce a pen which shall comply with the above requirements, or at least more nearly approach them than has been heretofore done. To accomplish these objects I make the reservoir A of a single tubular piece, closed airtight near its upper end by a diaphragm, b, as shown in Figs. 2 and 7. I then provide another diaphragm, I, of a diameter to fit easily within the lower open end of the handle or reservoir A, as shown in the several figures. This diaphragm I has formed in it a crescent-shaped hole or slit to receive and hold the pen-point B, as shown in Fig. 6, there being a slight enlargement of this slit opposite the back of the pen, thus leaving, after the pen B is inserted, a small opening, m, as also shown in Fig. G, through which opening both the ink and the air are to pass, as hereinafter explained. From the under side of this diaphragm I a lip, 0, extends down near the back of the pen B, and reaching to near its point, as shown clearly in Figs. 1, 2, 3, 4, and 7, this lip 0 being preferably formed integral with the diaphragm, although, if preferred, it may be made separate and be secured thereto. To the opposite or upper side of the diaphragm I is secured what I term a "feeding-stem," E, the object of which is to conduct the ink in the reservoir down to the hole m, as it is well known that the ink is liable to be held by capillary attraction of the side walls of the reservoir, aided by atmospheric pressure within the upper end of the reservoir, and more especially so if the reservoir be of small diameter. In order to render this feeding-stem more effective and certain in its operation, I make it preferably, as shown in Fig. 4, with a narrow groove, e, in one of its edges, as the two walls of this groove by their capillary action will cause the ink to flow down the groove with regularity and certainty, so long as any ink remains in the reservoir. It is obvious that the same result would be produced if the groove e were cut entirely through the stem, as the two walls would still be in close proximity, and therefore act in the same way; but they would be more liable to become bent or separated, and hence I prefer the plan shown. I also preferably make this stem E of such a length as to serve as a stop to limit the distance that the diaphragm I can be shoved into the open end of the reservoir A, as represented by the dotted lines in Fig. 2, in which it will be seen that the upper end of the stem E is in contact with the stationary diaphragm b, while the lower diaphragm, I, is a short distance within the open end of the reservoir A, thereby forming an open chamber, O, within the tube A below the diaphragm. This open chamber O serves as a receptacle for any excess of the ink which may be forced out of the reservoir by expansion or otherwise, it being held therein by capillary attraction; and if the pen be held or set with the point upward, or even in an inclined position, the excess of ink will soon pass from this chamber O back within the reservoir, it passing through the hole m., and being drawn back by the feeding-stem E. This chamber O also prevents the ink from working around to the outside of the handle A, as it would whenever there was an excess, if the diaphragm I were inserted, so as to be flush with the mouth of the reservoir, and this, together with the fact that there is no screw or other joint in the reservoir or handle at or near the point where it is held when in use, prevents the ink from coming in contact with the fingers. It is obvious, of course, that the chamber O might be formed by a short tube projecting from the lower face of the diaphragm and operate the same, in which case the diaphragm would not need to be shoved up into the reservoir at all; bub the plan shown is simpler, and is therefore preferred.

The special object of using the diaphragm I instead of the elongated plugs or sections formerly used in these pens is to insure a more easy, uniform, and certain feeding of the ink, which is an absolute necessity, in order to secure the best results in any fountain-pen. When a reservoir of this kind, in which the air enters at the same end at which the ink passes out is used, it will of course be understood that the ink will not flow out, except as air enters, and that the air will enter only in in proportion as the flowing out of the ink tends to create a vacuum within the reservoir, and that consequently the air will enter at intervals in the form of small globules or bubbles. If the channel through which these air-bubbles have to pass upward through the mass of ink flowing downward through the same channel be a long one, then the flow will be irregular, and at longer intervals, and thus the pen-point will at times be supplied with an excess and at other times with a deficiency of ink. Now, by using this diaphragm instead of a long plug, tube, or similar device, it will be seen that the hole or passage m through which the air and ink pass is a very short one, only equal in length to the thickness of the diaphragm, and that consequently the air-bubbles will pass through this short passage very quickly, and with more uniformity than through the long tubes or passages generally used. The instant a bubble passes through the opening or hole it rises through the ink in the reservoir to the upper end thereof, relieving the partial vacuum, and permitting the escape of a corresponding quantity of ink, and as this process is constantly recurring the feeding of the ink is thereby rendered uniform and certain. The ink, having passed to the lower side of the diaphragm I, is conducted by capillary attraction down between the pen B and the lip C to the point of the pen, which is thus kept uniformly supplied. By making the lip C flexible it can be extended down over the slit in the pen B to very near the point thereof, and thus the pen is kept supplied with ink, so that it does not become dry, even when permitted to lie unused for a long time, and is therefore always ready for use, it very seldom requiring to have its point moistened to start the flow of ink therefrom.

As it is desirable, for the reason above stated, to make the diaphragm as thin as is practicable, and as the pen B is held entirely by the diaphragm, I provide the pen B with lateral shoulders n, as shown in Pig. 5, so that when the end of the pen B is forced into the curved slit in the diaphragm these shoulders n will bear firmly against its under side, and thus aid to secure it more firmly in place and prevent any displacement or improper movement of the same when in use.

In order to enable the reservoir to be filled without taking the feeding-stem entirely out and laying it down, and which would be liable to smear the desk or papers with ink, I so construct it that it shall have sufficient friction against the inner walls of the reservoir to hold it in position when the diaphragm I is drawn out, as shown in Fig. 7. This may be done in various ways by simply bending it slightly, as shown in Pigs. 2 and 3, or by giving it several curves, as shown in Pig. 7, or by simply attaching it to a cross-piece, as shown in Pig. 4, the ends of which would serve to hold it in place by contact with the walls of the reservoir, or it may have its upper end split, as preferred. An equivalent method of arranging the stop would be to provide a projection, preferably in the form of a ring, l, as shown in Fig. 2, within the tube A, and make the stem B of the proper length to abut against it; but I prefer, especially if the tube A be of small diameter, to have the stem E extend all the way to the top of the tube, as it insures the feeding down of the ink,which might otherwise be held in the upper end of the tube by capillary attraction.

While I prefer to construct the several parts as shown, it is obvious that they may be slightly modified without changing the principle or operation of the pen. For instance, the stem E and the lip C may be made in one piece and be made to project through a hole in the diaphragm down by the side of the pen B, and on either its front or back side, preferably the latter; or the diaphragm I, lip C, and stem E may all be made in one piece. So, too, instead of the crescent-shaped opening m, a round hole may be substituted, and it may be located at the front or rear or on both sides of the pen; or, as shown in Pig. 8, a separate hole, I, may be made for the air, as I find by experiment that the ink will be drawn by the capillary attraction of the adjoining surfaces of the pen and lip into the narrow space between them as soon as it has passed through the diaphragm, whether it be delivered at the front or rear side of the pen. If a separate air-hole, l, be used, it will be filled with ink, so that the air will have to pass up through it, the same in effect as when but a single hole is used. It is therefore merely a matter of choice for the manufacturer as to which of these details he will adopt in the manufacture of the pen. By this construction I find also that I can make these pens very much smaller in diameter than usual, even reducing them to half the diameter shown in Fig. 1, thus specially adapting them to the requirements of ladies and children.

I am aware of the Several patents granted to P. E. Wirt, and also to others long before, in which various forms of lips and tubes have been used to feed the ink from the reservoir to the pen, and therefore I do not claim such a device, broadly; but

What I do claim isó

1. The combination, in a fountain-pen, of the tubular reservoir A, closed at its upper end and made without any joint near its lower end, with the diaphragm I, provided with the lip C and pen-point B, said diaphragm having a hole for the passage of air and ink, and being constructed and adapted to be shoved up into the lower end of the tube A, substantially as shown and described.

2. In a fountain-pen, the feeding-stem E, provided with the groove e, or equivalent slit, located within the ink-reservoir and extending from the diaphragm I upward to or near the upper end of said reservoir, said groove or slit terminating at the diaphragm, for the purpose of conducting the ink from the upper portion of the reservoir down to the diaphragm, substantially as shown and described.

3. In combination with the reservoir A, the diaphragm I, arranged to slide up into the open end of the reservoir, with the feeding-stem E, arranged to act as a stop by having its upper end strike against the closed end of the reservoir or, against a projection therein, and thus hold the diaphragm at the desired point within the reservoir, substantially as shown and described.

4. In a fountain-pen, the combination, with the reservoir A, of the diaphragm I,or section to which the pen-point is secured, and a feeding-stem, E, bent or otherwise provided with means for supporting it by frictional contact with the walls of the reservoir when the diaphragm is drawn out, substantially as and for the purpose set forth.

5. In combination with the diaphragm I, provided with a slit for the insertion of the upper end of the pen-point, the pen B, provided with the right-angled shoulders n, arranged to bear against the diaphragm I, substantially as and for the purpose set forth.

George H. Sackett

Witnesses:

Walter S. Dodge

W. C. Dodge

- Partnership: Thomas Davis, George P. Tew, and Lauriston Towne, in 1860-1880, in Providence RI. As SACKETT, DAVIS & Co., manufacturing jewelers.

|